Assembly and Packaging Capabilities

Packaging Capabilities

At T&R Tooling, we offer a diverse range of packaging solutions tailored to meet the unique needs of our clients. Our packaging services include bagging, shrink wrapping, and boxing, utilizing materials such as plastic and cardboard. We also provide custom packaging specific to each customer’s requirements. Our packaging size capabilities range from 12”x8”x5” for shrink oven packages, up to 12” wide x 20” long bags, and cardboard boxes as large as 48”x48”x48” gaylords.

While we do not provide design services for custom packaging, our expertise in handling a variety of packaging formats ensures that your products are securely and efficiently packed. Our equipment includes film pull conveyors, shrink ovens, auto bag machines, inkjet printers, label application systems, and pallet wrapping machines. We guarantee efficiency and accuracy in our packaging processes through weight verification and visual inspections.

We provide reliable options without compromising quality. Our packaging process begins with understanding the specific requirements of each client. We work closely with our clients to determine the best materials and methods for their products, ensuring both protection and cost-efficiency.

In addition to standard packaging solutions, we offer specialized packaging tailored to unique product needs. This includes the capability to handle delicate items that require extra care during shipping and handling. Our team is trained to manage various packaging challenges, ensuring that every product reaches its destination in perfect condition.

Packaging Services We Provide

These are just a few of the offerings we can provide and the equipment we use to perform our Packaging services:

- Bagging (Standard or custom printed)

- Shrink wrapping

- Boxing

- Palletizing

All of these processes are performed on-site by the highly qualified T&R Tooling professionals.

Assembly Capabilities

Our assembly services at T&R Tooling are focused on manual mechanical assembly, specializing in plastic-to-plastic and metal-to-plastic assemblies. Our assembly staff is proficient in screw driving, bagging, snap-together assemblies, and bar coding. To ensure the integrity of our assemblies, we utilize scales for bagged quantity verification, perform pull testing and perform visual inspections.

Our manual assembly processes are designed to handle complex and intricate products that require a high level of precision. Each assembly project is managed by experienced technicians who ensure that every component is assembled correctly and securely. This meticulous attention to detail is critical for maintaining the quality and reliability of the assembled products.

We also integrate barcoding into our assembly services, providing clients with efficient inventory management and tracking solutions. This is particularly beneficial for clients with large-scale operations that require accurate and timely information about their products. Our barcode systems are compatible with various industry standards, ensuring seamless integration with our clients’ existing systems.

Quality and Standards

Quality control is paramount at T&R Tooling. We conduct visual inspections and perform weight checks as required. In the event of defects or issues, we complete an 8D document to identify root causes and implement long and short-term corrective actions. Our adherence to industry standards is reflected in our AS9100 and ISO 9001:2015 certifications, as well as our UL certification.

Our commitment to quality begins with our rigorous inspection processes. Each product undergoes multiple checks throughout the packaging and assembly stages to ensure that it meets our high standards. This includes both visual inspections and weight verification, providing a comprehensive assessment of each product’s quality.

When issues are identified, our 8D problem-solving approach ensures that we address both the immediate issue and its underlying causes. This methodical process involves detailed analysis and collaboration with our clients to develop effective solutions. By focusing on both short-term fixes and long-term improvements, we continuously enhance our processes and prevent recurring issues.

Assembly Services We Provide

These are just a few of the assembly offerings we can provide:

- Barcoding

- Snap-together assembly

- Fastener assembly

All of these processes are performed on-site by the highly qualified T&R Tooling professionals.

Client and Industry Focus

We proudly serve clients such as Cantex, Pinnacle Safety Products, Jonell Filtration Group, Tescor and others, offering customized solutions to meet their specific needs. We handle both small and large order quantities, working closely with our clients to find the best possible solutions. Our post-assembly services include stocking programs to ensure timely delivery of parts, supported by our expanded facility and tripled warehouse space.

Our client-focused approach is at the heart of everything we do. We understand that each client has unique requirements and challenges, and we are dedicated to providing solutions that address these specific needs. Whether it’s a small batch of specialized products or a large-scale production run, we deliver consistent quality and reliability.

Our stocking programs are designed to provide clients with a reliable supply of their products, reducing lead times and ensuring they have the inventory they need when they need it. This service is particularly valuable for clients with high-volume demands or those who require just-in-time delivery to manage their production schedules.

Customer Support and Satisfaction

At T&R Tooling, we ensure client satisfaction through on-time delivery and quality production every time. Our collaborative team of experienced staff is dedicated to providing efficient and timely support, ensuring that our clients’ needs are met promptly and effectively.

We believe that excellent customer service is just as important as the quality of our products. Our team is always available to assist clients with their questions, concerns, and special requests. We provide personalized support, working closely with each client to understand their specific needs and deliver solutions that exceed their expectations.

Our commitment to on-time delivery is backed by our efficient production and logistics processes. We understand that timely delivery is crucial for our clients’ operations, and we strive to meet every deadline without compromising on quality. This reliability has earned us the trust and loyalty of our clients, who know they can depend on us for their packaging and assembly needs.

Future Plans

Looking ahead, T&R Tooling is excited to announce the expansion of our facility, which will increase our assembly production area staging us for growth and efficiency improvements as well as significantly enhance our warehouse capacity. This expansion will allow us to better accommodate our clients’ stocking programs and continue to grow our assembly operations.

Our plans for the future include investing in new technologies and equipment to further enhance our capabilities. By staying at the forefront of industry advancements, we aim to provide our clients with the most innovative and efficient solutions available. This commitment to continuous improvement ensures that we can meet the evolving needs of our clients and maintain our position as a leader in the packaging and assembly industry.

Ready to get started?

If you have any questions about our services or processes please contact T&R Tooling at any time.

We are ready to assist you with any questions or concerns you may have and welcome every opportunity to help you with your needs.

Call or email T&R Tooling using the information provided or use our easy to use forms to contact us anytime.

Telephone: (940) 726-6020

Email: tr@trtooling.com

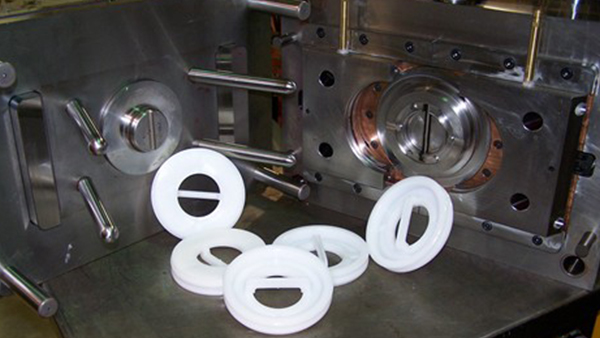

Plastic Injection Molding Texas

T&R Tooling offers plastic injection molding in Texas from 101 to 528 ton (5 to 65 ounce shot capacity) with core pull and robotic interfaces. Through a close alliance with our affiliates we have access to presses with capacities up to 1000 tons.

Our plastic injection molding shop near you in Texas is fully equipped to handle all fixturing and secondary operations should this be a requirement for your parts.

Assembly & Packaging

T&R Tooling’s expert custom packaging and manual assembly services. We offer bagging, shrink wrapping, boxing, and more, with a focus on quality and timely delivery. Our certified processes ensure the highest standards for your products.

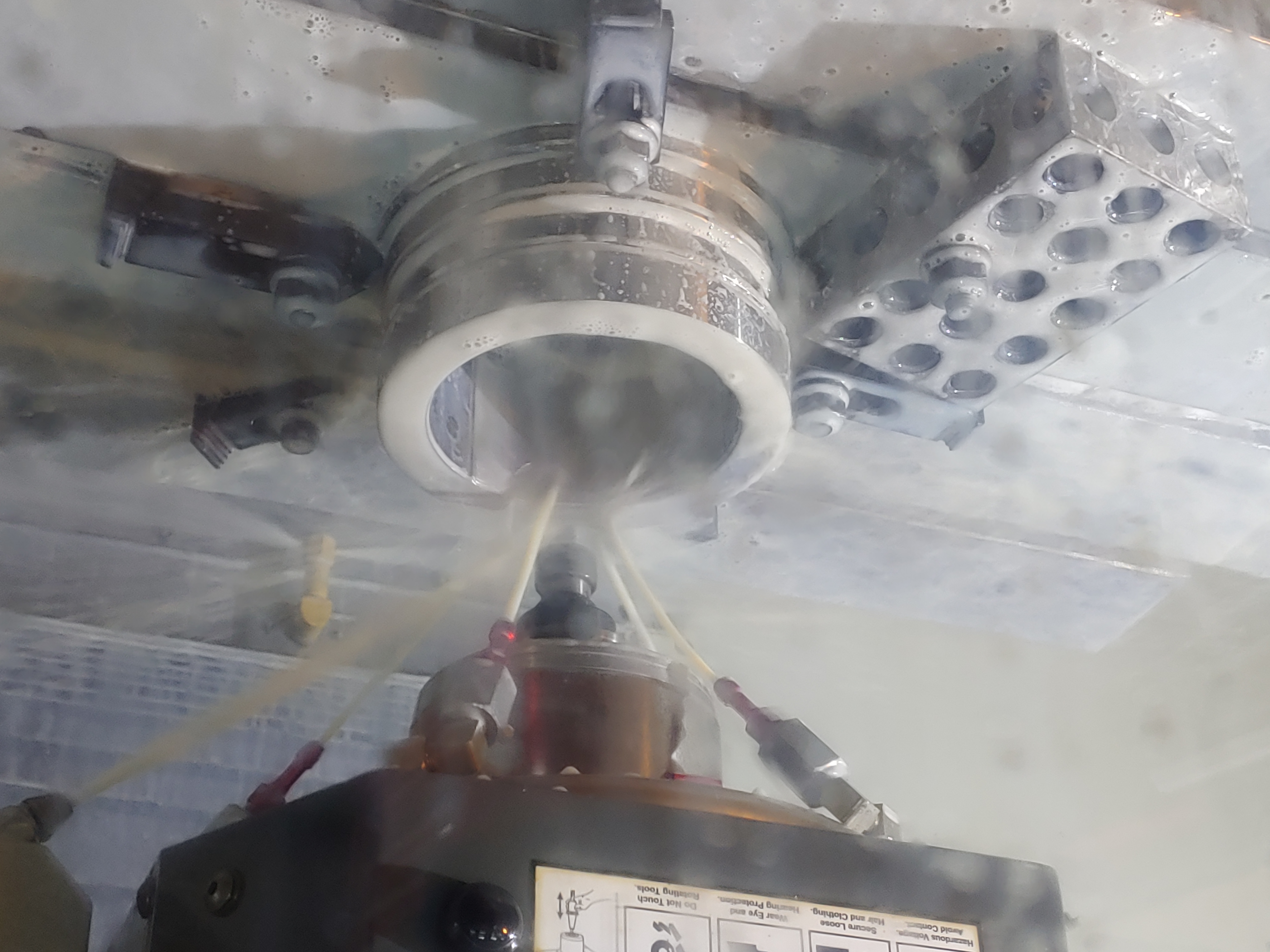

CNC Precision Machining

Our highly skilled injection mold building machinist team is ready to help you with you current or upcoming project. We excel at customer satisfaction. The T&R Tooling staff go the extra mile when it counts whether we are repairing a existing mold or constructing a new one for you. We would love to work with you on your next project.